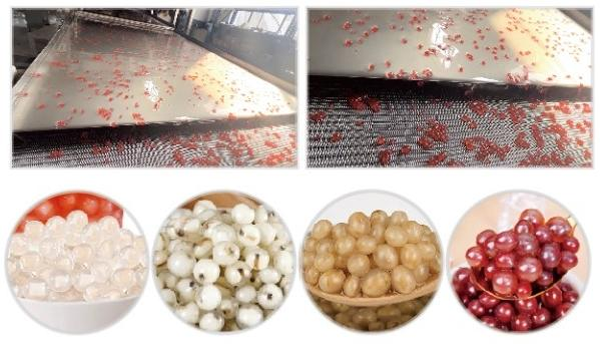

Popping boba production line/ automatic Agar ball froming production line

Popping boba production line / automatic Agar ball production line:

Product material: 316 stainless steel

Product specifications: customized according to demand

Application field: applied to agar balls/Popping boba

Product taste: smooth taste, uniform and full

Molding method: round, oval, customizable shape

Product size: 5-30mm, customizable and adjustable

Product weight: 0.8g~25g/grain

Output: 1-2T/H, can be customized according to demand

Main ingredients: carrageenan, sodium alginate, konjac gum, agar, etc., equipment can be changed according to customer formula requirements.

Use: room temperature, low temperature, cold drinks are all available; can be used for milk tea, fruit drinks, milk drinks, cake decoration, egg tart fillings, ice porridge, etc.

Product items: juice flavors (strawberry, mango, blueberry, green apple, sweet orange, lychee, grape, etc.), chocolate, etc.

The agar ball Popping boba froming molding production line adopts PLC control system and is fully automatic.

The machine integrates mechanical, electrical, gas and control. The electrical components, motors, electrical boxes, etc. are made of stainless steel for waterproof and splash-proof treatment; the filter is made of food-grade Teflon material and the edges are sealed with aramid cloth.

The structure is reasonable and compact, with a high degree of automation; the production efficiency is high, and the agar crystal balls produced by this production line are bright in color, round and beautiful in appearance, and delicious in taste.

The machine is equipped with a research and development system, which can realize full-automatic operation of the entire line. After many improvements, the operation is simpler and more convenient.

The entire production line is manufactured according to the food GMP standard, making it easy for food companies to pass professional certifications such as GMP, HACCP, and QS in the food industry.

Product advantages:

1. Threadless appearance and sanitary design.

2. All machines are made of SUS 304, and the material and thickness are much higher than those of peers.

3. Our machines can produce pearls from 5mm to 30mm in size. It can suit your needs.

4. We are the first manufacturer of popping pearls in China, and the machine has been upgraded 3 times. So far, our machines are very mature.

5. We have an exclusive formula for Popping boba, and customers can directly put them into production according to the formula.

6. We have many customers from the United States, and they have very good feedback on our machines. If you need, I can provide a customer list for customer reference.

7. Before delivery, the entire production line is tested to ensure that customers can use the machine directly after receiving it.

8. The entire line is divided into 4 parts. When you receive the machine and just make some simple plugs, you can start your production.

2. Equipment configuration list

Agar ball production line, Popping boba production equipment includes the following systems: water treatment system, juice blending system, agar blending system, titration molding system, cleaning and curing system, sterilization system, cooling system, heating system, packaging coding system.

Production process:

1. Colloid is rehydrated by colloid grinding

2-1. Add water, sugar, carrageenan, sodium alginate, konjac gum, agar, etc. to the sandwich pot for boiling and heating.

2-2. Boil and heat the calcium water to melt and stir

3. Pump the boiled and calcium water to the storage barrel for temporary storage.

4. The colloid storage tank is vacuumed.

5. The cam rotor delivery pump quantitatively delivers the materials in the storage tank to the hopper and the water tank respectively. The liquid in the water tank is cooled by the chiller.

6. The molding machine is molded

7. Cooling

8. Customization

9. Collection

10. Packaging

11. Sterilization.

1 Colloid mill

Since sodium alginate is slightly soluble in water and insoluble in most solvents. It dissolves in alkaline solutions, making the solution sticky. Sodium alginate powder becomes wet when it meets water, and the hydration of the particles makes its surface sticky. Then the particles quickly stick together to form clumps, which are slowly hydrated and dissolved. Therefore, this equipment is needed to assist sodium alginate to dissolve in water and increase the dissolution rate.

Model: JM-L50 Emulsification fineness (um): 2~50 Output: 0.2~0.5T/h

Grinding disc size: 50 Inlet: 47 Outlet: 20

Speed (r/min): 2900 Motor power: 1.5kw

Machine size: 460×340×800 Weight: 68kg

2 Cooking system equipment

2-1. Vertical sandwich pot (with stirring)

This equipment is mainly used for cooking jam liquid and coagulation liquid raw materials, using scraping stirring.

Steam heating and electric heating are required.

Working temperature: 0℃~150℃.

Electric heating power: 24kw

Motor power: 1.5kw

Capacity: 400L

2-2. Cooling tank

This equipment is mainly used to reduce the temperature of raw materials after cooking and for temporary storage.

Motor power: 1.5kW;

Capacity: 500L

2-3 Delivery pump

Mainly used for conveying liquid raw materials. The pump body is made of 304 stainless steel.

Diameter: 1”; Flow rate: 3.3 m3/h, 55l/min.;

Pressure: 0.32MPa; Speed: 1420r/min; Motor power: 1.1kW.

3. Molding unit:

The molding unit includes a froming system, a material tray conveying system, a sodium alginate circulation system, a bead filtration system and a cleaning system. PLC+touch screen.

3-1. Basic parameters:

1) Total power: 8kw,

2) Output: 200~300kg/h

3) Machine size: 5400x2200x2250mm

4) Weight: 2000kg

5) Working environment: >25℃

6) froming speed: 15~25times/min;

7) Product size: Dia8-15mm (can be made into 5mm diameter, up to 25mm diameter, need to be customized);

3-2. The unit includes equipment:

1) Control box (the control box can also be fixed on the machine)

2) froming head

3) Sodium alginate circulation system

4) Product filtration system

5) Cleaning system

6) Buffer system

7) Filter system

3-3. Quality requirements

1) The whole machine is made of 304 stainless steel, and the nozzle is generally made of copper nozzle. Stainless steel nozzle is not durable and can be selected according to customer requirements.

2) Waterproof treatment;

3) The filter screen is made of Teflon material.

3-4) The pump body is 304 stainless steel

3.Popping Boba &Brusting Boba

Popping boba,also called popping pearls,is a type of "boba"used in bubble tea.Popping boba is made by the reaction of sodium alginate with calcium chlorideor calcium lactate.Popping boba has a thin,gel-like skin with juice inside and it can burst when squeezed.The ingredients for popping boba generally consist of water, sugar,fruit juice and other flavors,and the ingredients required for spherification.In addition to being used in traditional bubble tea,it is also used in smoothies,slushies,yogurt,bakery and other food.

4.Agar Boba &Konjac Ball

Agar boba&konjac ball is a slightly chewier alternative than boba.It is made from plant-derived agar,which makes it best served with bubble tea!It is a healthier alternative than traditional tapioca pearls,made with

high-quality konjac powder from Taiwan.Experience the perfect balance of

with these syrup-rich aromatic chewy konjac balls.It is quick

use.You only need to add it in your favourite drinks or

and then you can enjoy extra burst of flavor.Versatile and

convenient -enjoy on its own,or use to enhance a

variety of dishes and beverages.

Fully Automatic Popping Boba/Agar Ball Production Line

The automatic popping boba/konjac ball production line was developed exclusively .It adopts PLC control system.The whole set of machines is made of stainless steel and fully complies with food sanitation standards.The fully automatic production line mainly consists of colloid mill cooking system,popping boba/konjac ball forming machine,and tipping cooking tank for protective liquid.The popping boba made by this machine is in beautiful round shape,bright color,and with very litte waste material,which can produce popping boba/konjac ball with variety colors&flavors based on the advanced technology process.

MODEL

| P80 | P100 | P200 | P500 |

Capacity | 50-80kg/h | 80-100kg/h | 200-300kg/h | 400-500kg/h |

Boba weight

| According to boba diameter (Customized from 3~30mm or more)

|

Depositing Speed

| 15~25 Strike/min

| 15~25 Strike/min

| 15~25 Strike/min

| 15~25 Strike/min

|

Motor Power

| 0.37kW/380V/50HZ | 4.5kW/380V/50HZ | 6.5kW/380V/50HZ | 8kW/380V/50HZ |

Compressed Air

| 0.5M3/min,0.4~0.6MPa | 1.2M3/min,0.4~0.6MPa | 1.5M3/min,0.4~0.6MPa | 2M3/min,0.4~0.6MPa |

Machine size

| 2400X800X1550mm | 8500x1300x1780mm | 9250x1700x1780mm | 11500x1700x1780mm |

Gross weight

| 200kg | 2200kg | 3000kg | 3800kg |

Simulation Caviar Popping Boba Production Line

automatic simulation caviar production line is mainly composed of cooking system, forming system and central control system.The production line has a high degree of automation and is easy to operate.The main components are made of food-grade 304 or 316 stainless steel,which fully meets the requirements of food hygiene.The produced artifcial caviar has a round shape and bright color,and the product size can be made into 3-5mm,which can be used to replace pure natural sturgeon caviar.

In addition to making imitation caviar popping boba,this machine can also make popping boba with ordinary diameter (8-10mm).The capacityis larger than ordinary models,and the maximum can reach 1.8t/h.

Model |

Capacity | Depositing speed | Boba size | Depositing Nozzle |

PS200 | 100-150k/h | 25-30n/min | 3-4mm | 4352pcs/n(dual hopper) |

PS400 | 300-500kg/h | 25-30n/min | 4-6mm | 3264pcs/n(dual hopper) |

PS1500 | 1200-1800kg/h | 25-30n/min | 9-11mm | 1632pcs/n(dual hopper) |

Konjac Ball Production Line

continuous production line independently developed in 2009.The production line is fully servo controlled easy to operate and stable in production.It is your best choice for the crystal boba production line.The equipment can produce konjac ball of different sizes by changing the mold and adjusting the parameters of the equipment operation screen. The mold replacement is simple,and the production capacitycan reach 200-1200kg/h.The equipment technology is mature. Contact us for more information.

Model | CJQ200 | CJQ400 | CJQ600 | CJQ800 | CJQ1000 | CJQ1200 |

| 0-200kg/h | 0-400kg/h | 0-600kg/h | 0-800kg/h | 0-1000kg/h | 0-1200kg/h |

Water Chestnut /Highland Barley / Red Bean Juicy Pearl Production Line

The CMT production line processes edible

horseshoes/grains/oats/red beans into various grain popping beads, mixes calcium lactate powder and tapioca powder and finished products through high-speed stirring,and wraps them in round equip- ment,and finally slides them through the chute to produce the balls. Grain popping balls are round in shape and rich in taste,and are widely used in bubble tea shops,etc.

SemiAutomatic Popping BobalAgar Ball Forming Machine

The semi-automatic popping boba /konjac ballforming machine is fully developed .It adopts a pneumatic control system.The machine includes depositing hopper,forming liquid circulating system,final product washing system,etc.Our machine fully complies with food sanitation standards,whole machine is made of stainless steel and can be used safely.When using this machine,manually pour the juice syrup into the hopper,and the sodium alginate liquid or calcium liquid can be circulated below.The popping boba or konjac ball made by this machine has beautiful and uniform shape,and bright color.By adjusting the recipe, the filling can be any taste.

Model |

Capacity |

Depositing speed | Boba size | Compressed air |

P10 | 10kg/h | 10-30n/min | 5-35mm | 0.4-0.6Mpa |

P30 | 30kg/h | 10-30n/min | 5-35mm | 0.4-0.6Mpa |

P50 | 50kg/h | 10-30n/min | 5-35mm | 0.4-0.6Mpa |

Kitchen Equipment Series

Colloid Mill

This machine has multiple functions such as mixing,stiring,dispersing,homogenizing,emulsifying.homogenizing,etc.It has strong versatity,stable and uniform production.Especilly in the production process of dairy products,food and pharmaceuticals,no powder

lumps,no particles,no agglomerates formed.

Compared withthe traditional process,it can shorten the working time by 80%,greatly improve the production efficiency and reduce the

production cost It is not onlysuitable for continuous automatic production lines,but also suitable for diferent batch production applica- tions.Itis especilly suitable for high-viscosity and refractory materials (viscosity 90,000mPas);the equipment has no dead angle,and can be completely online CIP/SIP,which meets hygienic requirements and standards.

SPECIFICATIONS

Model |

Water Flow (Processing Capacity(T/h) |

Emulsification Power(kw) |

Self-Priming Pump Power(kw) | Stirring Speed(r/min) |

TG-A-165 | 0.3-3 | 4 | 2.2 | 2800/1480 |

TG-B-165 | 0.3-4 | 5.5 | 2.2 |

TG-B-180 | 1-6 | 7.5 | 5.5 |

Colloid Mill

Colloid mill is an equipment for fine grinding of fluid and semi-fluid materials.Can be

processed according to the requirements of the material,through the fixed teeth and

rotating teeth high-speed operation,so that the material under the strong shear force.

This machine has and other efficiency. It is widely used in superfine grinding,dispersing,emulsifying,homogenizing,mixing food industry,chemical industry,pharmaceutical industry,daily chemical industry,construction industry,paper industry,battery industry,etc.

C-A Series Cooking And Cooling System

The cooking and cooling system is used forcooking,cooling,and storing inner and outer materials.The heating method can be electric heating or steam heating.The individual outer materials are cooked and stored in a single system,and the inner

materials are also cooked and stored in a single system,each system is on a frame with a separate electrical control box,

which is convenient for operation and maintenance.The kettles have the

characteristics of a large heating area,uniform heating,short liquid cooking time,

and easy control of heating temperature.Whole machine SUS 304 material,

optional for high-speed shear and vacuum system.