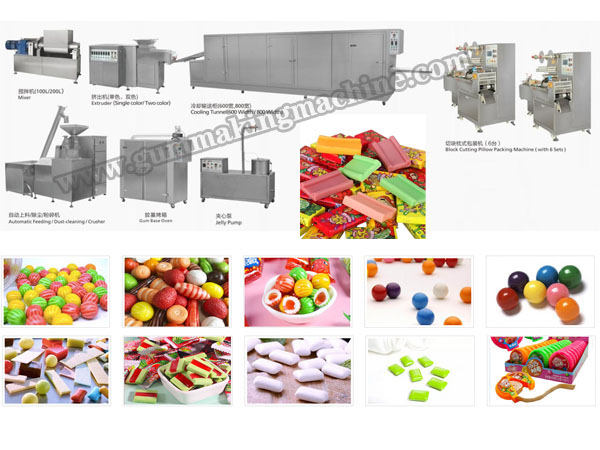

chewing gum production line

The full-automatic chewing gum production line can produce round, spherical, square, rectangular, sheet and other shapes of chewing gum. The chewing gum production machine is reliable, flexible, simple and automatic.

Automatic chewing gum production line

The automatic chewing gum production line is composed of a mixer, an extruder, a six-pass flattening machine, a forming machine, a cooling conveyor cabinet, an automatic granulator, a glue-based oven and a coating machine. It can produce various shapes of chewing gum (such as round, spherical, square, rectangular, sheet, etc.). The whole machine is reliable in production, flexible and convenient in operation, and automatic. It is a chewing gum processing equipment.

Process flow of automatic chewing gum production line

Mixer - extruder - six passes of flattening - forming machine - cooling conveyor cabinet - automatic granulator - rubber base - oven - coating machine - packaging machine

Bubble gum making machine

Bubble gum making machine

Full-automatic bubble gum making machine can produce spherical bubble gum, square bubble gum, special-shaped bubble gum, sandwich bubble gum and other forms of bubble gum. The whole production line consists of a mixer, an extruder, a cooling conveyor cabinet, a three-layer conveyor belt, a molding machine, and a sugar coating machine

Main performance of automatic bubble gum making machine

Full-automatic bubble gum making machine is an automatic production line integrating shape, cutting and packaging. It is applicable to the forming, cutting and packaging of milk sugar, bubble gum and toffee. It has the characteristics of high production efficiency and less secondary sugar. We can produce products of various shapes and specifications according to customers' requirements. Such as chewing gum, Swiss candy slice, rectangle, round paste, color, sandwich, etc.

Process flow of automatic bubble gum making machine

Automatic feeding/dust removal/pulverizer - blender - extruder - cooling conveyor cabinet - block pillow packing machine - low temperature double vacuum aerated mixing pot - rubber oven

Automatic xylitol gum production line

This fully-automatic Automatic xylitol gum making machine consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of xylitol Gum。

Process flow chart of xylitol gum making machine

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Popping boba production line

Full-automatic popping boba production line (full-automatic konjac flour popping boba production line)

The automatic popping boba production line adopts PLC program and touch screen, which is easy to operate and accurately control the size of the popping boba crystal ball head. A full range of SUS304 stainless steel supports customization, workshop planning and installation from engineers to factories.

Model: ZY50, output/hour: 20-50kg, machine weight: 2000kg

Model: ZY100, output/hour: 50-100kg, machine weight: 2200kg

Model: ZY200, output/hour: 200-300kg, machine weight: 3000kg

Model: ZY500, output/hour: 400-600kg, machine weight: 3800kg

Model: customized output according to customer demand

Product features and use:

The complete set of equipment of the automatic popping boba production line includes the hopper, SUS pot, flushing system, cleaning system, etc. The whole production line is mainly made of stainless steel, which is widely used in milk tea, catering, caviar and other industries